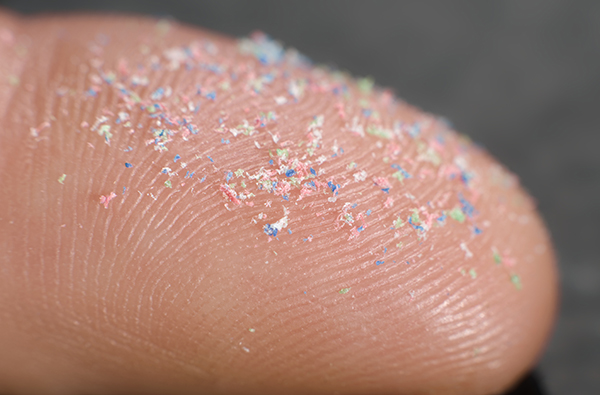

The fibers found in carrots, sugar beets, and other root vegetables are good for digestion and beneficial bacteria in humans. The nanoplatelets in those fibers were used to strengthen concrete mixtures, increasing the strength of the construction material while also making them more environmentally-friendly.

The vegetable-composite concrete mix is the work of Lancaster University engineers and their partners at Cellucomp Ltd. U.K. It is supported by the Horizon 2020 project of the European Union.

Earlier testing showed that concrete mixtures with nanoplatelets possess much better mechanical properties. The plant-based additives even outperformed other commercially-available counterparts like graphene and carbon nanotubes, which says a lot given those two are considered to be supermaterials.

The nanoplatelets have two ways of boosting the strength of the concrete. First, they increase the amount of calcium silicate hydrate, the substance responsible for much of concrete's mechanical properties.

Second, like the blood component with which they partly share a name, the nanoplatelets also stop cracks from forming in the concrete. Strengthening concrete in these ways allow smaller amounts of the material to be used during the construction of buildings. (Related: Researchers use graphene to make new and improved concrete.)

Carrot fiber helps make concrete stronger while reducing carbon dioxide

The construction industry generates a significant amount of air pollution. Eight percent of the world's total carbon dioxide emissions are attributed to the manufacture of ordinary Portland cement, which is one of the important ingredients for concrete. The pollution is expected to double within the next 30 years as new construction increases the demand for concrete.

The Lancaster researchers reported that every cubic meter of their vegetable-composite concrete mix saves 40 kilograms of ordinary Portland cement. In carbon dioxide terms, that translates to saving 40 kg of CO2 as well.

"These novel cement nanocomposites are made by combining ordinary Portland cement with nanoplatelets extracted from waste root vegetables taken from the food industry," explained study leader Mohamed Saafi, a professor at Lancaster University. "The composites are not only superior to current cement products in terms of mechanical and microstructure properties, but also use smaller amounts of cement. This significantly reduces both the energy consumption and CO2 emissions associated with cement manufacturing."

Professor Saafi added that the microstructure of the vegetable-based concrete mixture was much denser than normal concrete. It could resist corrosion much better and last much longer.

The research team is considering strengthening already-built concrete structures with the addition of slender sheets of vegetable nanoplatelets. Concrete beams that are being supported by these sheets will be able to bend more, thereby avoiding taking damage.

Improving concrete and paint with plant fibers

The Lancaster researchers are continuing to investigate the myriad processes through which the root vegetable nanoplatelets improve the concrete mix. They are optimizing the mixture so that it can one day be used by the construction industry to build stronger, safer, and more eco-friendly buildings.

Cellucomp Ltd., meanwhile, is already using knowledge derived from this research to improve another common product's strength and environmental friendliness. The company is making paints with improved durability thanks to the addition of root vegetable fibers.

“We are excited to be continuing our collaboration with Professor Saafi and developing new applications for our materials, where we can bring environmental and performance benefits,” said Dr. Eric Whale, a member of Cellucomp Ltd. who worked alongside his Lancaster University counterparts.

Inventions.news holds more articles about improvements to everyday materials that make them better for the environment and for us.

Sources include:

Please contact us for more information.